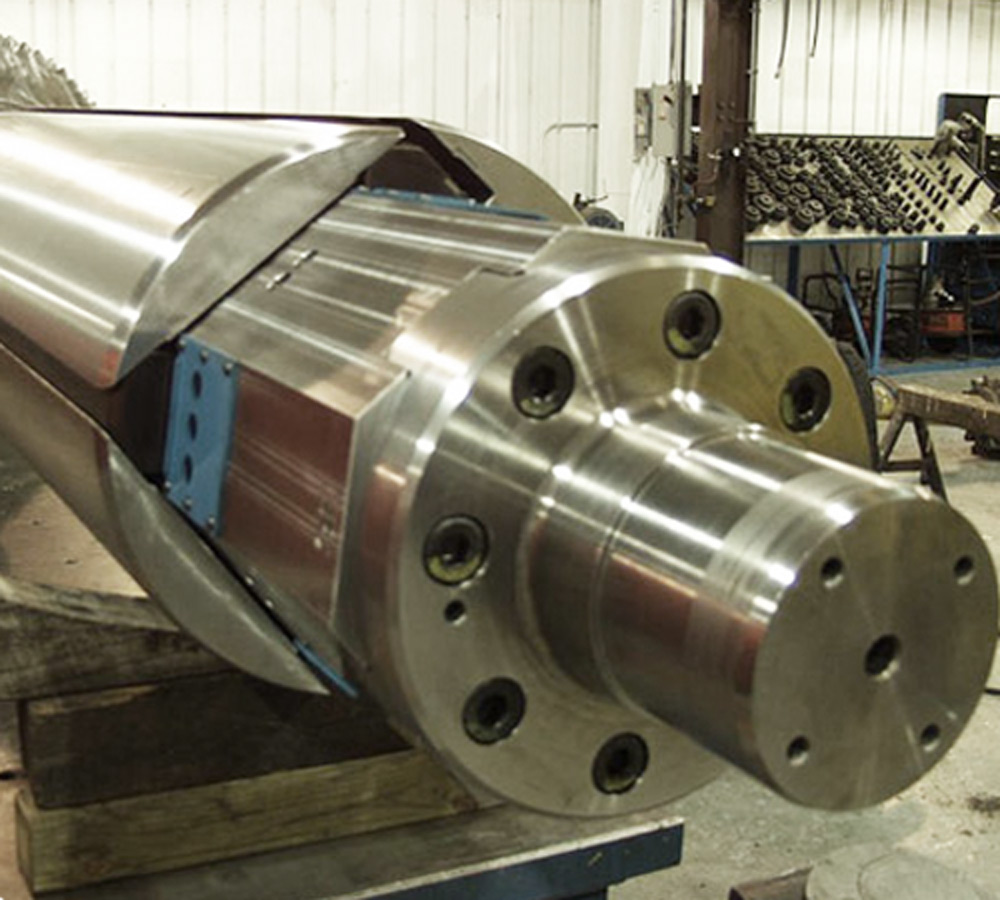

Aeromet "Stick and Run" Reversing Mill Mandrel for the Steel Producing Industry

01. Challenge

A steel producing industry client charged Aeromet with the task of designing and manufacturing a mandrel drum that was capable of tremendous gripping power, yet had a simplistic design for ease of maintenance and longevity.

02. Approach

Aeromet’s experienced engineers worked with the customer to determine their requirements, and designed and manufactured the "stick and run" mandrel. To machine this part, we used a CNC Ryazan lathe, CNC Union floor bar mill, CNC Giddings and Lewis bar mill. Made from 4340 steel HT to 160,000 yield and 4140 steel, the mandrel was CNC machined to 24" x 234", weighed 22,000 lbs. and met tolerances of ±.002". We applied chrome plating and ion nitriding with a turned or milled finish.

03. Results

After extensive inspection of the components during the production process and full testing of the mandrel once it was completed, our machining process met ISO 9001:2015 standards and fulfilled all of the client’s requirements.

To learn more about this CNC machined Aeromet "stick and run" tension reel project, contact us directly.

| Product Description | Aeromet Stick and Run Tension Reel |

| CNC Machining Capabilities Applied/Processes |

Primary: Engineering, CNC Machining, Assembly, Installation |

| Equipment Used to Manufacture Part | Autodesk Inventor® and CNC Union Floor Bar Milling Machine |

| Overall Part Dimensions | 24" x 220" |

| Tightest Tolerances | .002" |

| Material Used | Mild, 4140, 4340 Steel Heat Treated to 160,000 Yield Strength |

| In process testing/inspection performed | Extensive post production testing and extensive in process inspection of components |

| Estimated Part Weight | 22,000 lbs |

| Industry for Use | Steel producing, Cold Mill, single stand reversing mill |

| Delivery Location | Midwest, USA |

| Product Name | Stick and Run Mandrel |