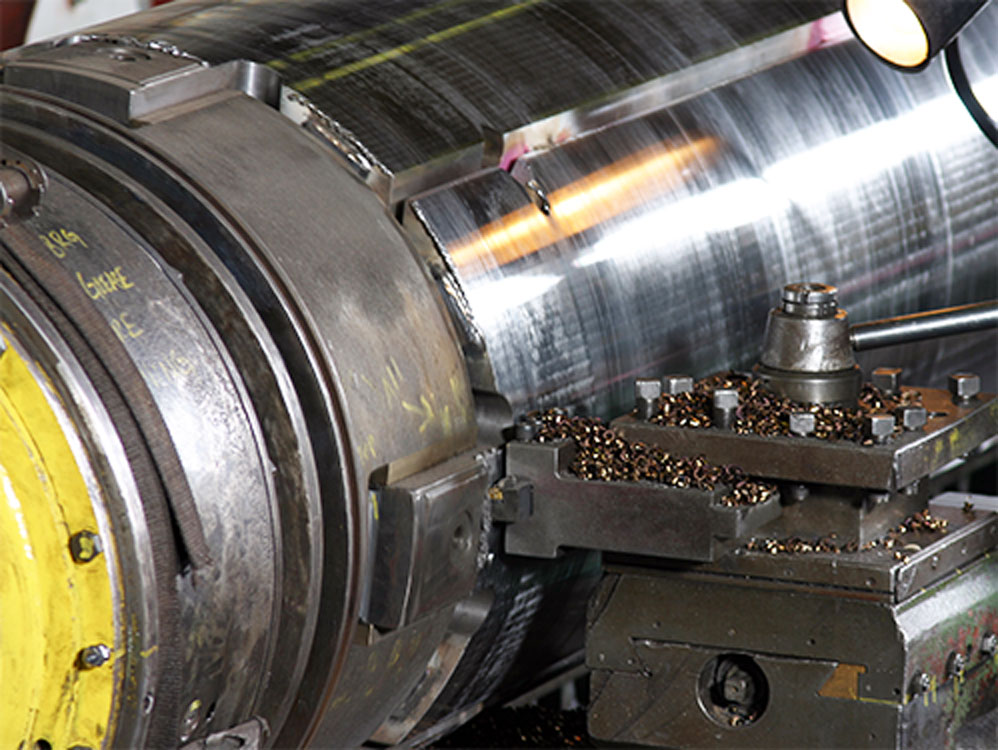

Large Capacity Machining

Aeromet offers CNC machining for large components, with applications in a variety of industries. From prototype production to medium runs, our team of experts uses machinery to handle complex jobs and achieve consistently high-quality results.

Executing all Phases of Manufacturing

Rely on Aeromet for a wide range of machining processes including milling, drilling, turning, pressing and threading. In addition, we provide in-house tooling, reverse engineering, CAD design and assembly.

State of the Art Equipment

Utilizing our state of the art vertical and horizontal machining centers and large swing lathe, we machine steel, aluminum, alloys, titanium, stainless steel and exotics, plus plastics to 394”L x 138”W x 84”H. Our turning capacity is up to 433”L and 72”D. We utilize 3 axis CNC machining capabilities, with 3- and 4-jaw chuck fixturing, and can accommodate materials up to 50 tons.

Transportation Services

Once the machining of your large component is complete, Aeromet can provide safe transportation of the constructed equipment for delivery to your location. For more information on our heavy and large component custom machining or our other services, please contact us today.

| Machining Processes |

|

| Equipment |

|

| Equipment Capabilities |

|

| Fixturing |

|

| Materials |

|

| Turning Diameter |

|

| Turning Length |

|

| Milling Length |

|

| Milling Width |

|

| Milling Height |

|

| Maximum Lifting Capacity |

|

| Secondary Services Offered |

|

| Production Volume |

|

CASE STUDIES

Aeromet Industries, Inc was approached by a client in the steel producing industry to design and manufacture a mandrel drum that was capable of tremendous gripping power and a simplistic design for ease of maintenance and longevity.